Alcoholic Drink

Filling Machine

We use the gravity-filling machine, negative pressure filling machine, and counter-pressure filling machines for alcoholic drinks. The Counter pressure-filling machine is for beer since it is carbonated. And gravity filling machine and negative pressure filling machine are for noncarbonated alcohol, like vodka and whisky.

Principle of Alcohol Filling Machine

Linho uses a micro negative pressure filling for non-carbonated alcohol. Because it has no drips as a gravity filling machine, and a smaller vacuum helps maintain the flavor of the drink.

The filling tank is under negative pressure. When the bottle/can seal with a filling valve, the bottle will have the same negative pressure as the filling tank. Then the alcohol flows into bottles. When the alcohol level reaches the vent, the filling stops.

Structure of Bottle Filling Machine

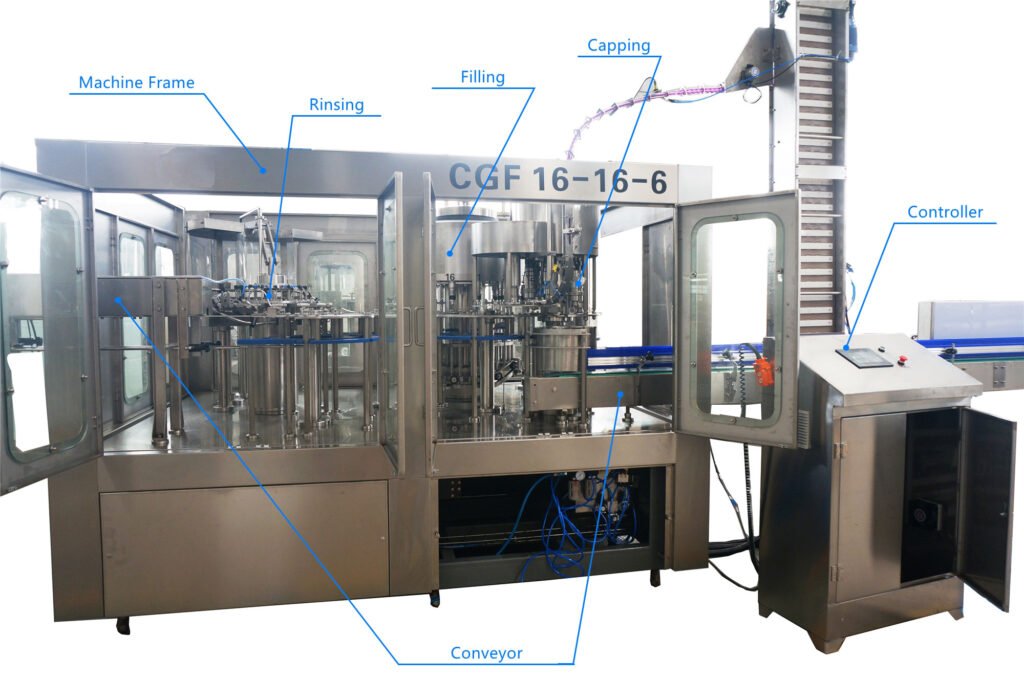

Alcohol Beverage Filling Machine consists of a bottle washing machine, a filling machine, a capping machine, a worktable, an inlet and outlet bottle arc plate, star wheels, motor drivers, a frame and control system. Bottle holder holds the bottle neck or bottom, then send it under the action of star wheel between bottle washing, filling and capping machines.

Bottle Washing Machine

Bottle washing machine consists of bottle washing clamp, upper turntable, guide rail, water distributer, protective cover, water spray device, water collecting tray. All parts in contact with the liquid is SS304 or SS316. The bottle wash clamp is integrally molded, and lubricating parts of the active part is from Igus. It is more durable than ordinary bottle washing clamp for 5 years.

Filling Machine

Filling machine consists of filling tank, filling valve, control ring, lifting device, etc. The liquid contact part is SS304 or SS316, and the thickness of the filling tank’s bottom plate is up to 30mm. The filling valve is Germany style and was manufactured by China’s top filling valve company.

Capping Machine

Capping machine consists of bearings, lifting worm gear components, transmission gears, capping heads, cams, machine reducers, etc. According to different bottles and customers’ requirements, we can use a plastic cap, crown cap, aluminum cap, twist-off cap, pull-over cap, etc.

Filling Process of Alcohol Drink Filling Machine

Air conveyor/conveyor sends bottles to star wheel. Star wheel sends bottles to bottle washing machine. There are bottle clamps on washing machine. Bottle clamps clamp the bottle neck and flips 180° along the guide rail to let the bottle mouth down. In the specific area of the bottle washing machine, washing nozzle sprays water into bottles to rinse the inner wall of bottles. Star wheel sends bottles to capping machine. The stop knife on the capping machine locks the bottle neck, keeping the bottle upright and preventing rotation. The capping head keeps the revolution and rotation on the capping machine, and realizes the action of cap grabbing, cap covering, cap screwing and cap releasing under the action of the cam. Star wheel sends bottles from the capping machine to the bottle conveyor. Bottle conveyor sends bottles to next machine.

After washing and draining, bottles flip 180° along the guide rail to let bottle mouth up. Star wheel sends transfer the bottle under the filling valve. Filling valve Press the bottle mouth to form a seal.

And vacuum the bottle. When the vacuum level in the bottle is consistent with the vacuum level of the filling machine tank, filling begins.

When the liquid in the bottle reaches the vent tube, the filling stops. The filling valve leaves the bottle. The bottle enters the sealer.

Star wheel sends bottles to capping machine. The stop knife on the capping machine locks the bottle neck, keeping the bottle upright and preventing rotation. The capping head keeps the revolution and rotation on the capping machine, and realizes the action of cap grabbing, cap covering, cap screwing and cap releasing under the action of the cam. Star wheel sends bottles from the capping machine to the bottle conveyor. Bottle conveyor sends bottles to next machine.

Know More About The Alcohol Drink Production Line

Q1: Can The Alcohol Drink Filling Machine Fill Beer?

No. Beer needs the counter pressure filling machine. Please check below links of beer.

Q2: How Does Alcohol Filling Machine Keep Constant Liquid Level in The Bottle?

The length of the vent decides the height of the liquid level. Keep the same vent length, bottle shape and size, the liquid level is always at the same height.

We can change the sealing gasket thickness or vent length to change the liquid level.

Q3: How to Fill Multiple Bottles at Once?

Bottles with the same neck size, and the bottle diameter difference isn’t more than 5mm, one set of filling machine can fill them all.

If the bottle has the same neck size, but the bottle diameter difference is more than 5mm, we will need the bottle change parts. Each set of bottle change parts is customized according to the bottle size. The bottle change parts include the bottle star wheel and bottle fixing parts.

If the bottle neck size is different, we will need the change parts mentioned earlier. Moreover, all parts in contact with the bottleneck. For example, the bottle neck holder, clamp, the capping head, and the seat.

Q4: Can The Alcohol Drink Filling Machine Fill Aluminum Cans?

Yes.

The filling principle for cans, plastic bottles, or glass bottles is the same. We just need to make specific parts for different containers.

Q5: If The Bottle Cap Is Different, How Can I Adjust it?

For glass bottle, we can use crown cap, aluminum cap, twist-off cap, pull-over cap, etc. Each kind of cap, the capping head is differert. When change caps, customer need extra capping machine. Linho can make 4 in 1 filling machine with 2 sets of capping machine. Each time, use one set of capping machine.

Q6: What Labeling Machine, Date Printer And Packing Machine Do You Need?

Plastic bottles usually use shrink labels and OPP labels.

Glass bottles are self-adhesive labels or bottle printed.

Plastic and glass bottles are available with ink printers and CO2 laser date printers.

Metal containers such as aluminum cans can use ink printers and fiber laser date printers.

If you are producing glass bottled beverages, a grab-type cartoning machine is a better choice. When the production line speed is low, manual packing is also an excellent choice with only one sealing machine. If the local carton packaging materials are more expensive, and there is not much restriction on plastic packaging materials, you can choose a shrink film packaging machine to save the cost of machines and packaging materials.

Q7: How To Make Whisky?

Whisky is made from barley and it has an alcohol concentration of 50%-60% and has malt aromas. The filling machine is the negative filling machine. It is the same as vodka. Popular cap is aluminum.

The Whisky production line process has 7 steps: Malting – Mashing – Fermentation – Distillation – Aging/Maturing – Blending – Bottling. Please check the detail to see how it is made.

Q8: How To Make Beer?

Beer is an alcoholic beverage fermented from malt. It has a unique flavor and low alcohol content. It’s one of the favorite drinks at people’s gatherings and parties.

Beer generates much CO2 during the fermentation process. So the filling machine should be counter pressure filling machine.

The brewing process of beer can be divided into Malting – Mashing – Saccharification – Fermentation – 2nd fermentation – Filtration – Filling Packaging.

Please check the detail how it is made.

Alcoholic Drink Market

The global alcoholic drink market is equal to 515.2 billion USD in 2019. Until 2023, the drinks market in the world is expected to reach 647.7 billion USD .

The global alcoholic drink market is growing at a CAGR of 7% during the forecast period 2021 – 2023.

The Trend Of Alcoholic Drink

Beer segment is the largest in the market. It drives the alcoholic beverage market globally.

Consumers’ inclination towards to flavored drink contributes to the growth of the alcoholic drink market. Companies launch new product to meet demand.

Due to the increasing number of global young-adult, and high disposable income, premium and super-premium products is becoming preferred. It is anticipated to be the major driver in the global alcoholic drink market in 2020-2027/.

The Impact of Covid-19

The market grew less from 2019-2020 because of the elecnomic slowdown across countries. However, it is expected to recover from 2021.

Machines In A Alcohol Bottling Machine Line

Take a peek inside our Wonderworld

Packing Material For The Alcohol Bottling Machine Line

Bottles

Glass bottles are the main packing containers for alcohol drink due to they have less impact for the drink flavour. Aluminum cans are usually used for low alcoholic drink like beer and flavor drink.

Caps

Aluminum cap, crown cap, pull-ring cap are for glass bottles. Wood cork is the popular type for red wine. However, more companies adopt aluminum cap for red wine nowadays owing to its convenience. Lids is for metal cans.

aluminum caps

crown caps

pull-ring caps

lids

Labels

Self adhesive label and glue label are usually for glass bottles and made from paper.

Packing Material

Shrinking film packing and carton packing are the main packing types.

Please contact us to share your idea.

We will help you to set up the Alcoholic Drink business no matter in machines , raw material or the factory design.