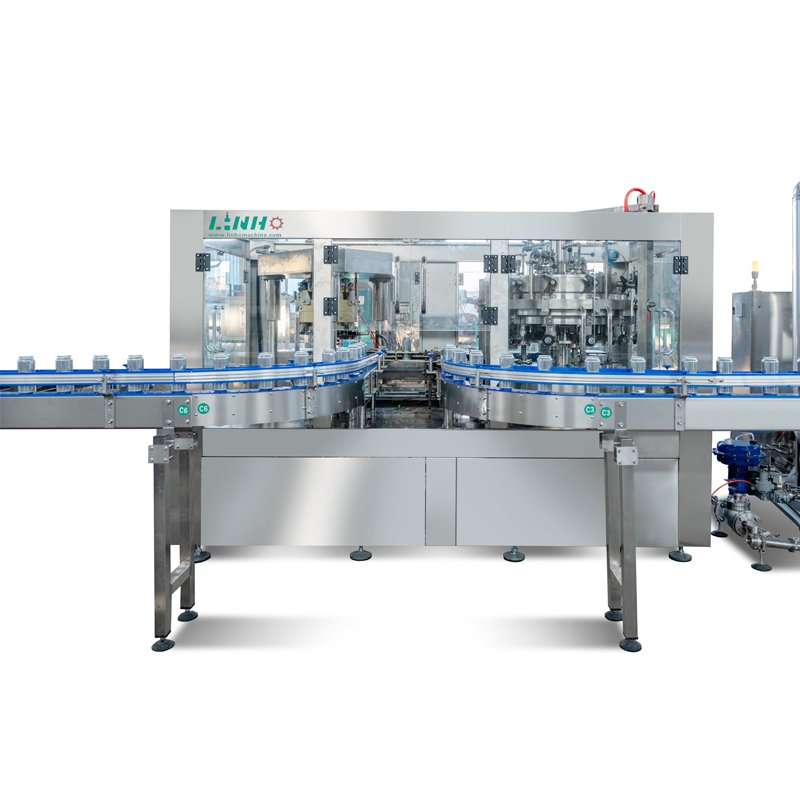

Carbonated Drink Can Filling Machine

In A Complete Canning Drink Production Line There Are Can Depalletizer, Can Rinsing Machine, Can Spraying Warming Tunnel, Ink Date Printer, Can Twister. PET Can Or Metal Can Is Optional.

Additional information

| Speed | 2000-18000CPH |

|---|---|

| Filling Theory | Counter Pressure |

| Control Type | PLC & HMI |

| Machine Type | Filling & Seaming Integrated |

View Videos

Details of Carbonated Drink Can Filling Machine

Aluminum Can Filling Machine Character

It is filling machine and seaming machine set, with PLC, frequency converter and HMI.Setup the production speed on the touchscreen. Machine alarm automatically of all common malfunctions and show the cause and position of malfunction, PLC detect and decide to continue or stop the machine according to the level of malfunction.

Can Filling Machine Structure

Workbench, filling valve, centering unit, Blow and exhaust switch components, valve open and close unit, filling tank and height adjusting device, can inlet conveyor, can separating device, inlet star-wheel and guide, can lifting holder, cam stand, hook chain, lid feeding device, can holding disk, seaming machine, seamer, sealing roll, covering, outlet conveyor, can outlet star-wheel, driving system, electric system, etc.

Can Filling Machine Parameter

|

MODEL

|

12-1 | 12-4 | 20-4 |

30-6 |

|

SPEED CANS/HOUR |

2000 | 3000-5000 | 10000 |

18000 |

|

FILLING POSITION |

12 | 12 | 20 |

30 |

|

CAPPING POSITION |

1 | 4 | 4 |

6 |

|

CAN DIAMETER |

65MM(customized) |

|||

| CAN HEIGHT |

122-166MM(customized) |

|||

Share Carbonated Drink Can Filling Machine To Your

LINHO Filling Factory, established in 2012, is committed to manufacturing liquid filling machines. We aim to make the purchase of Chinese filling equipment fast and efficient. Explore now to view the newest releases from LINHO.

Links

- Small fillling solutions

- Warehouse equipment

Contact

- Industrial Park, Zhangjiagang

- +86 512 58186265

- +86 13372192902

- info@linhomachine.com

- Shanghai Airport