What Is Filling Machine?

A filling machine is a piece of industrial equipment used to dispense and package various types of products, such as liquids, powders, granules, or even small solid items, into containers like bottles, cans, jars, pouches, or other types of packaging. The main purpose of a filling machine is to accurately measure and transfer a predetermined quantity of the product into each container, ensuring consistency, efficiency, and proper packaging.

Filling machines come in various designs and configurations depending on the specific type of product being filled and the packaging requirements. Different industries, such as food and beverage, pharmaceuticals, cosmetics, chemicals, and more, use filling machines to streamline their production processes and maintain product quality.

What Kind Of Filling Machines Does Linho Make?

Linho’s main products are liquid filling machines, which are mainly for beverage and food. Such as water, juice, beer, wine, CSD, porridge, paste, ketchup etc. Our Filling machines are suitable for PET bottles, glass bottles, cans, jars, gallon bottles.

Linho makes different types of filling machines, including:

- Gravity Filling Machines: It is for filling liquids like water, juices, oils, sauces, beverages, and more.

- Volumetric Filling Machines: These machines fill a fixed volume of product into each container, often using mechanisms like pistons, rotary valves, or pumps.

- Vacuum Filling Machines: It is for filling liquids into bottles without causing foaming or spillage. We usually use vacuum filling machine for wine, juice, or high speed filling production line.

- Overflow Filling Machines: Suitable for filling foamy liquids, these machines ensure consistent fill levels by allowing excess product to overflow. We usually use the overflow filling machine for juice, high speed water filling.

- Piston Filling Machines: Utilize a piston to accurately measure and dispense products. We usually use this piston filling machine for thicker liquids or products with particulates. Like oil, honey, juice with pulp.

- Counter Pressure Filling Machines: Inflate CO2 into the packaging container to make the container pressure equal to filling machine tank. Then fill liquid product into the packaging container by its gravity. Suitable for beverage with CO2. Such as beer, CSD, champagne.

- Siphon Filling Machines: Using the siphon principle, suck the liquid product from filling machine tank into the container through the siphon. Suitable for wine, water, vinegar, soy sauce.

- Timing Filling Machines: Control the filling time to set the filling quantity. So the liquid level of each bottle is the same. Suitable for gallon bottled water filling.

20L/5 Gallon Bottle/Big Jar Water Filling Machine

20l Jar Filling Machine Is Mainly Used To Produce Bottled Water With Volume From 3 Gallon To 5 Gallon. And Different Models Can Offer Production Capacity From 100 To 3000 B/H.

PET Bottled Juice Beverage Bottle Filling Machine Line

The Machine Is Designed Based On Hot Filling Technology, Suitable For Filling Juice, Tea, Coffee, Etc. Various Bottles 200ml-2L. Speed Is From 2000bph To 20000bph.

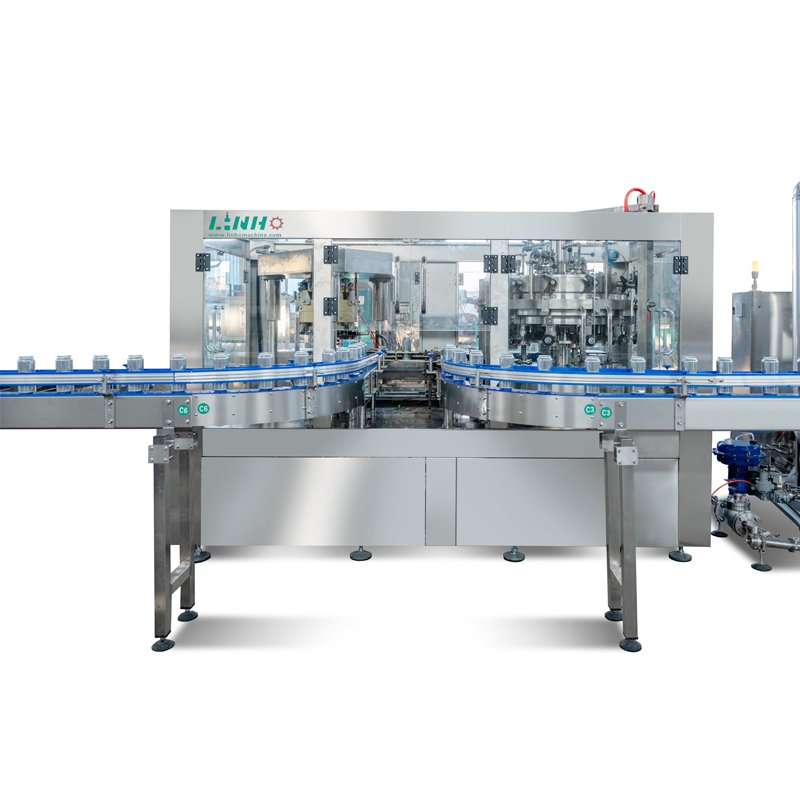

Carbonated Drink Can Filling Machine

In A Complete Canning Drink Production Line There Are Can Depalletizer, Can Rinsing Machine, Can Spraying Warming Tunnel, Ink Date Printer, Can Twister. PET Can Or Metal Can Is Optional.

PET Plastic Bottle Mineral Water Filling Machine

Bottled Drinking Water Filling Machine, Its Filling Method Is Gravity Filling. Gravity Filling Machine, Also Known As Atmospheric/Normal Pressure Filling Machine, Means That Under Atmospheric Pressure, It Directly Relies On The Weight Of The Filling Material To Flow Into The Packaging Container. This Kind Of Filling Is Only Suitable For Filling Liquid With Low Viscosity And No Gas.

PET Bottle Water, Low Cost, Easy To Carry, And Diversified Bottle Design. It Is The Main Way Of Drinking Water Packing In The Market.

How Do These Filling Machines work?

A filling machine includes a bottle rinsing machine, bottle filling machine, and bottle capping machine. To realize the filling machine automation, it also has bottle feeding and outlet conveyor, cap elevator, and cap sterilizing tunnel.

Empty bottles enter onto a conveyor system or a rotary table, which moves them to the bottle rinsing machine. Rinsing machine inverts and rinse bottles with water or a sanitizing solution to remove any dust, debris, or contaminants. After rinsing, bottles keep going to the filling machine. Different products and containers, the filling machines are different. We will clarify every filling machine one by one in our next articles. After filling, bottles proceed to a capping station where caps or closures are placed and tightened onto the bottles. This step may involve the use of cap sorting, placing, and sealing mechanisms. In the various stages of the filling process, sensors or mechanical devices detect the presence of bottles and control their movement.

How Does A Gravity Filling Machine Work?

A gravity filling machine is a type of liquid filling machine that relies on the force of gravity to fill containers, such as bottles, with liquids. It is a relatively simple and cost-effective filling method that is commonly used for filling non-carbonated liquids, such as water, juice, oil, and other similar products. Following is to show how a gravity filling machine works:

Bottle Feeding:

Load empty bottles onto a conveyor system, which transports them to the filling station. There are bottle base holders(for glass bottle) and bottle neck holders(for plastic bottle) to hold the bottles in place to ensure proper alignment during the filling process.

Bottle Orientation:

When fill glass bottle, there is a part called “centering cover” to guide bottles into the filling station, where they are positioned correctly under the filling nozzles to ensure accurate filling.

Filling Nozzles:

The filling nozzles are positioned above the bottles and are connected to a filling tank which has product inside. The nozzles are equipped with valves that control the flow of liquid.

Valve Opening:

There is a sealing gasket on the filling valve. Under the function of cam, bottle was lifted to contact with filling valve, and then sealed with the sealing gasket. A lifted bottle opens the filling valve, the filling starts. Liquid flows from the supply source into the bottle due to the force of gravity. The height difference between the supply source and the bottle creates the necessary pressure for the liquid to flow downward.

Liquid Flow:

The liquid flows into the bottle, filling it gradually. When the liquid reaches the vent, which is in the middle of filling valve, the filling stops. So vent length determines the liquid level inside the bottle

Bottle Removal:

After filling, the bottle is released from the bottle holder or clamp and continues along the conveyor system to the next stage of the packaging process, such as capping, labeling, and packaging.

What Is The Advantage Of Gravity Filling Machine?

- Simple and easy to operate.

- Suitable for filling non-carbonated liquids without foaming issues.

- Minimal mechanical complexity, leading to lower maintenance requirements.

- Cost-effective solution for smaller-scale production or startup operations.

What Is The Limitations Of Gravity Filling Machine?

- May not be suitable for products with high viscosity or those prone to foaming.

- Slower filling speed compared to some other filling methods.

- Can be less accurate in achieving precise fill levels compared to more advanced filling methods.

Gravity filling machines are a popular choice for small to medium-sized production lines where the emphasis is on cost-effectiveness and simplicity. They are well-suited for filling various liquids into containers and are widely used in industries such as food and beverage, cosmetics, and pharmaceuticals.

In one word, filling machines play a critical role in automating the packaging process, reducing manual labor, minimizing product waste, and maintaining consistent product quality. The choice of filling machine depends on the type of product, its viscosity, the desired packaging format, and the production volume. Linho is pleased to work with you to find the best filling solution for you. Please contact us!