For the food industry, workshop hygiene is undoubtedly one of the most important links for enterprises. In addition to strict management, a clean workshop is questionably another important guarantee for workshop hygiene. How much does it cost to invest a clean workshop in beverage factory? The bottled water clean-filling workshop includes changing rooms, air shower rooms, pre-entry rooms, partition walls, ceilings, and fresh air systems. First, we need to determine how big is the construction area. The lower the clean level value, the higher the clean level. For bottled water, levels of 100,000 to 10,000 are enough.

We need on-site measurement and communication with each customer before designing the plan and quoting the price. The following is the decoration design of the clean filling workshop of the beverage factory-made by LINHO company.

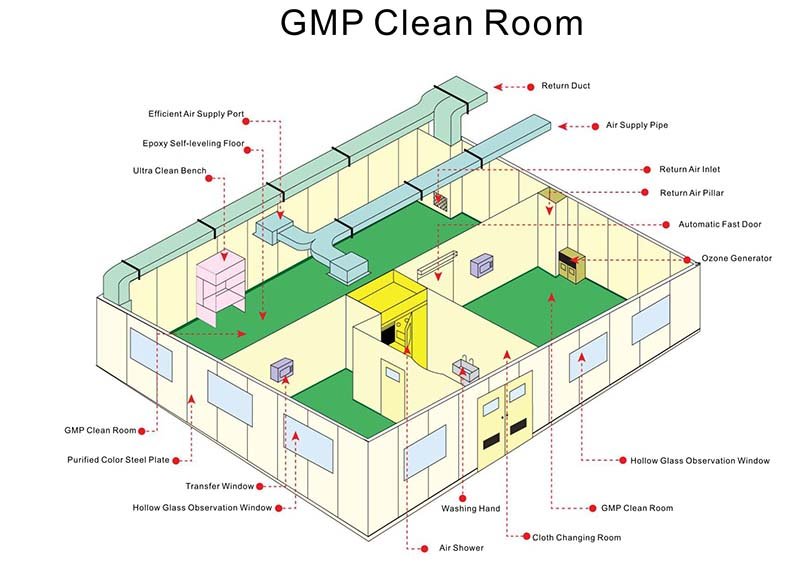

Description of clean workshop in beverage factory

A beverage speech workshop is best isolated from the outside world, not passed through or disturbed by other factors. The size of the filling clean workshop of the beverage factory depends on the need, which is generally composed of a changing room, buffer room, air shower room, and operation room.

- The changing room is placed outside, mainly for changing clothes, hats, shoes, and so on;

- The buffer room is located between the changing room and the air shower room, and can also be communicated with several operating rooms simultaneously;

- The operation room is located in the inner room, mainly for product filling. The room should be free from direct sunlight and of appropriate size and height (determined based on the height of the production equipment). The room is too large, making it inconvenient to clean and disinfect; Too small, inconvenient to operate; The top is too high to affect the effectiveness of ultraviolet light sterilization. The walls are smooth without dead corners for easy cleaning and disinfection.

- The food/beverage sterile clean workshop should be enclosed and maintain a positive static pressure difference, equipped with ultraviolet lamps for air disinfection, an air filter, and a constant temperature device.

Building layout of clean workshop in beverage factory

The building layout should belong to the professional category of architecture. Due to the separation requirement of people and objects in the filling clean workshop of the beverage factory, and the need to maintain the static pressure gradient of each clean operation room, the building layout of the project requires the following:

- We need to set the independent front chamber of each clean operation room as an airlock, and the airlock room is communicated to each operation room simultaneously to ensure that the air in the low cleanliness area does not penetrate the high cleanliness area.

- The flow of people in the laboratory passes through the changing room to change clothes and shoes – wash hands in the cleaning room – buffering room – air shower room – each operating room.

- The beverage factory clean workshop logistics are carried out from the outer corridor via the mechanical chain from the disinfected pass box disinfection into the buffer corridor and then via the pass box into each operation room.

Decoration of the clean workshop in beverage factory

- The workshop’s walls and ceilings must use materials that do not produce or accumulate dust, have a smooth surface, and have no dead corners.

- The color board should be a specific color board for clean plant construction, the substrate’s top plate should be 0.4mm steel plate, the core material density should be 14kg/m3, and the aluminum material should use dedicated aluminum profiles.

- All aluminum profiles are electrophoresis treated to improve the service life of the clean room and achieve a beautiful and elegant effect.

Structural materials for the clean workshop in the beverage factory

- The walls and top plates of the clean workshop, generally adopt 50mm thick sandwich-color steel plates, which have a beautiful appearance, strong rigidity, good insulation performance, and easy construction. The arc wall corners, doors, and window frames, generally adopt specific aluminum oxide profiles.

- The ground uses the epoxy self-flow floor or advanced wear-resistant plastic floor. If there are anti-static requirements, choose an anti-static type.

- The supply and return air ducts adopt hot-dip zinc sheets and are pasted with flame-retardant PF foam plastic sheets with good purification and insulation effects.

- The efficient air supply outlet has a beautiful and clean stainless-steel frame. The punching mesh uses a painted aluminum plate, no rust, no sticky dust, and is easy to clean.

Materials for the wall and ceiling of the clean workshop in the beverage factory

Color steel plate sandwich composite board is made of sandwich material using special high-strength glue and color steel plate surface layer composite, which are heated, pressurized, and solidified. The use of different sandwich materials, their performance, and technology differ, now described as follows. The color steel plates have different categories, such as polystyrene board, gypsum board, rock wool board, glass magnesium board, glass magnesium rock wool board, aluminum honeycomb board, paper honeycomb board, and so on.

According to the thickness of steel plates, there are several types, including 0.326, 0.376, 0.426, 0.476, 0.526, 0.576, etc. Generally, select materials based on the production use and actual construction situation in the production workshop.

Ground engineering of the clean workshop in the beverage factory

The ground adopts solvent-based epoxy resin with a strength of C20 or above, and the surface is dense with no sand, empty drum, or cracks. It has the character of bright color, consistent anti-static performance, moderate load resistance, and high-temperature resistance. It can play a decorative role based on meeting the requirements for use, with wear-resistant, washable, dustproof, anti-slip, excellent performance, and uniform color and luster.

Ventilation air purification equipment of clean workshop in beverage factory

Clean workshop design, design a supply and return air system by regulatory requirements. The machine room is located on the top side of the factory building (according to the actual situation, can use a unit-type purification system instead of a machine room), and each supply and return air circulation duct is connected to the air conditioning unit in the technical interlayer to form a system.

The supply and return air ducts adopt high-quality galvanized steel plates and are soft-connected through air valves. The galvanized steel plate air duct must be manufactured on-site.

Lighting of clean workshop in beverage factory

- The filling clean area should use ceiling-mounted purification lamps, and the non-clean area should use ordinary fluorescent lights.

- Design the lighting in each room, with UV lights controlled independently, controlled by the electrical control box, and then centrally controlled by the chief distribution cabinet.

- All indoor lighting adopts sealed lighting units;

- Socket panels all adopt embedded type;

- There is no open-wire laying indoors.

- The food industry has clear regulations on the moving line of personnel and materials, non-cross-flow,

- The material flow needs to set up a specialized material transfer port or transfer door;

- Personnel flow requires dedicated personnel channels.

- According to production processes, hygiene, and quality requirements, classify cleanliness levels, specific levels, and requirements.

Requirements for personal hygiene of clean workshop in beverage factory

- Employees (including temporary workers) should undergo health checks and undergo hygiene training and education;

- Do not wear work clothes, or shoes into the toilet or leave the production and processing site;

- Other personnel (including visitors) entering the production and processing site or workshop should comply with the specifications.

I believe that through this article, you already have a general understanding of the clean workshop in beverage factory, if you have any questions, please feel free to contact us. We look forward to talking with you!