According to economic theory, when marginal revenue equals marginal cost (MR=MC), the profit reaches its maximum in theory. As long as marginal revenue exceeds marginal cost, we will continue to expand production and earn all possible profits until marginal revenue equals marginal cost. During actual economic activities, theoretical profit maximization is subject to many constraints, such as limitations on invested capital, market capacity, production capacity, etc. How to maximize profits under limited resource conditions is a guiding and practical issue for arranging economic activities. How to optimize bottled water line?

Here, we take the bottled water production line as an example to discuss how to optimize bottled water line and improve the profit of products. To increase profits, the first thing everyone thinks of is nothing more than opening sources and reducing expenditures. How to implement it specifically? First, let’s talk about cost savings.

Reduce the cost of raw materials

As we all know, the cost of raw materials is one of the most significant costs for bottled water manufacturers. The raw materials here mainly include; plastic bottle preform, plastic caps, labels, and packaging materials.

Bottle preform:

The price of the bottle preform depends on the weight of the bottle preform. As an example, the gram of a 500ML water bottle is approximately 16-22g. To reduce the weight of bottle preform is to save the cost of bottle preform. How to reduce the bottle preform weight without affecting the firmness of the bottle? We can use more reinforcing ribs on the bottle body and a shorter bottleneck.

The main component of bottle preform is plastic, which is an international standard component. Affected by the price of raw plastic, the prices of bottle preform vary slightly in each country. We can choose a cost-effective supplier of bottle preform based on shipping costs, taxes, and other factors.

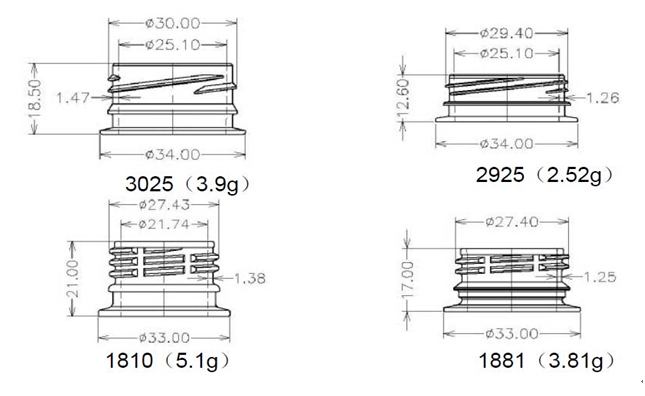

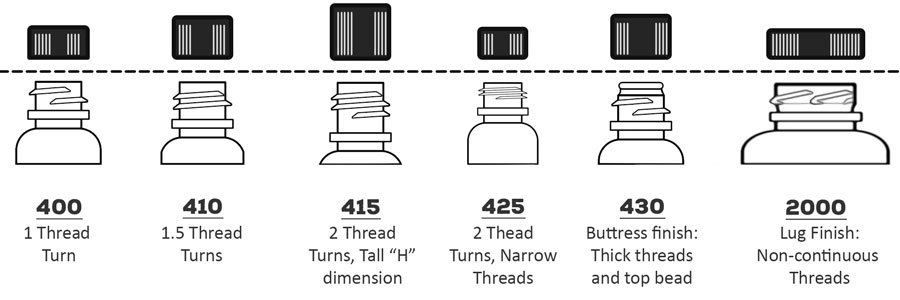

Bottle caps:

Using a short-neck bottle preform, we need to short-neck bottle cap to match the short-neck bottle preform. Undoubtedly, a short-neck cap is cheaper than a high-neck bottle cap. However, if your original production line uses a high-neck bottle cap, switching to a short-neck cap necessitates replacing the capping mold inside the capping head and the cap tunnel.

Label:

The common labels for bottled water are self-adhesive labels, shrink labels, and hot-melt glue OPP labels. The cost of hot-melt glue OPP labels is the lowest among them, and we can use a hot-melt glue OPP labeling machine to save label costs. Apart from the label machine and OPP labels, don’t forget to purchase the glue for the OPP label.

Packaging materials:

The packaging materials mainly include PE film and cartons. Transparent PE film is the most economical packaging material among them. If you choose cartons as packaging materials, one-piece cartons cost less than ordinary cartons.

Expand sales channels

Besides the traditional channels such as supermarkets and hotels, we can also produce customized water for special customer groups.

Enrich the product

Besides saving costs and expanding sales channels, we also can gain new profit points by enriching our products.

Enrich product appearance

Enriching the product appearance includes designing new bottle shapes, new label patterns, and new labeling and packaging methods. The new bottle shape requires a new mold, which not only replaces the molds of bottle blowing machine, but also causes adjustments to the filling machine, labels, and packaging machine parts.

Enrich product volume

If the existing production line is to produce 500ML bottled water, we can add 330ML, 1000ML, 1500ML, and another bottle volume. Normally, by adjusting the changing parts on the machine, we can produce 200ML-2000ML bottled water on one production line. If the bottle size is 3L-15L or 20L, it is a different production line machine.

Enrich product container

In addition to PET plastic bottles, water bottles include glass bottles, aluminum bottles, pop cans, and boxes. We can increase new profit points by enriching product containers.

Enrich product types

When our bottled water business matures, we can produce different products such as sparkling water, fruit juice, carbonated drinks, etc.

If you are planning to optimize bottled water line, contact us and LINHO will provide you professional suggestion as the machine manufacturer.