Today we will talk about the 5gallon palletizer.

Amy: It’s hot recently. The barreled water in the office is drinking too quickly. Please assist me in changing the water, David. The barreled water is heavy, how does the water factory store and transport it after finishing the production? If manual handling, it is tiring.

David: Aha, no need to worry about that. Now the automation level is so high that one set 5gallon palletizer can solve this issue, without manual work!

The invention of the palletizer is a boon for water plants, especially for places where labor is expensive. It not only saves labor cost but also significantly increase production speed!

What is the palletizer?

The palletizer is a device that automatically stacks cartons or other packaging materials on pallets (wood and plastic) according to the mode required process and transports the stacked products. The palletizer can stack multiple layers and then push them out to facilitate forklift transport to the warehouse.

The automatic palletizer is a high-tech product integrating machinery and electricity. It can complete the palletizing of bags, rubber blocks, boxes, and other products according to the required grouping mode and number of layers. It adopts PLC + touch screen control, and the optimized design makes the stack compact and tidy. The palletizer realizes intelligent operation and management, simple and easy to master, resulting in a significant reduction in the labor force and labor intensity.

The composition of the 5gallon palletizer

5gallon palletizer Tray/pallet

Typically, the number of barreled water palletizing layers is three, with each layer consisting of 12 barrels (3*4), 16 barrels (4*4), or 20 barrels (4*5). Pallets used for palletizing are typically firm at the bottom layer than at the other layers, though we can also use unified pallets. When the bottom pallet and the other layers of pallets are not the same, the automatic palletizing machine needs to consider the double pallet conveyor, as different pallets use different pallet conveyors.

5gallon palletizer Rack

There are empty barrel racks and finished barrel racks for the barreled water rack. There is no doubt that the finished barrel rack needs firmer.

Palletizer

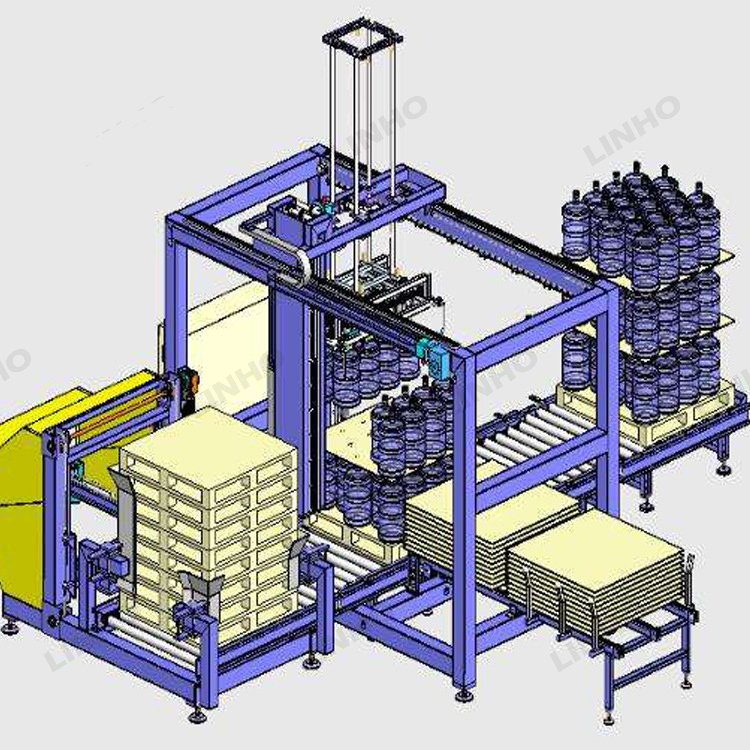

The palletizer is made up of the barrel enter conveyor, buffer conveyor, pallet bin, pallet conveyor, palletizing device, and finished pallet out conveyor.

5gallon palletizer, Safety fence and safety grating

In terms of safety, the palletizer must install a safety fence. To protect personnel safety, we can install a safety grating on the safety fence, and when personnel approach, stop palletizing.

Safety grating is a photoelectric safety protection device (also known as safety protector, punch protector, infrared safety protection device, etc. It is a kind of photoelectric equipment that prevents personnel from approaching mobile machinery, thereby reducing casualties.

The type of the 5gallon palletizer

According to the degree of automation, we can divide palletizers into semi-automatic palletizers and full-automatic palletizers.

According to the level of intelligence, we can divide full-auto palletizers into robot-type palletizers and mechanical-type palletizers.

Mechanical palletizer has gantry palletizer, column palletizer, and mechanical-arm palletizer.

Gantry-type semi-automatic 5gallon palletizer

- Palletizing: automatic palletizing

- Tray (bottom layer): manual taking and placing

- Tray (other layers): manual taking and placing

- Finished product pallet out: manual forklift get out the pallet

During production, manually place the tray (bottom layer tray) at the palletizing position, when the barreled water enters the palletizer, the barrel-grabbing mechanism grabs the barreled water onto the pallet. After stacking one layer, manually take the tray and place it on the barreled water, and then repeat the second layer of stacking. After completing the palletizing of one stack, manually fork out the pallet.

Rotary-type full-automatic 5gallon palletizer

- Palletizing: automatic palletizing

- Tray (bottom layer): machine automatic taking and placing

- Tray (other layers): machine automatic taking and placing

- Finished product pallet out: manual forklift get out the pallet

The finished barreled water through PLC under the action of a signal switch, counting and completing the arrangement on the platform, then the barrel clamping mechanism clamps the barrel mouth, lifts and rotates, and sends it to the barrel palletizing platform to realize the stacking of the finished barrel water.

In contrast to the semi-automatic palletizer, which places the tray (both the bottom layer tray and the other layers’ trays) manually, the automatic palletizer places all the trays by machine. The automatic palletizer automates the entire process, increasing production efficiency even further.

Robot type 5gallon palletizer

The robot palletizer is knowns as a palletizing robot, a manipulator palletizer, an industrial robot, and an automatic robot.

The robot palletizer consists of a mechanical body, a servo drive system, an arm mechanism, an end effector (gripper), an end effector adjustment mechanism, and a detection mechanism.

Main characteristic:

- Small occupation area, large production capacity, simple operation, easy maintenance.

- l Energy-saving and environmentally friendly arm design, flexible arm movement, and low energy consumption significantly reduce customer operating costs.

- Light and simple structure, low noise, few parts, and few accessories, reduce the machine failure rate, customer spare parts inventory, and low maintenance cost.

The advantages of Linho automatic rotary type 5gallon palletizer:

- Optimized structure design, less space occupied, large production capacity, smooth and reliable action.

- Adapt to varieties of stack types and bottle types, easy to adjust.

- Adopt a high-quality conveyor chain for segmented transmission, and we can lengthen the output section arbitrarily.

- The combination of high-quality hardware and control software designed by experts realizes a high degree of system automation.

- Software: international advanced automatic PLC control technology, mechatronics technology, network technology, computer control, full-automatic stacking process, reciprocating cycle automatic stacking meets the set requirements.

- Hardware: the chief control elements, including the programmable controller, variable frequency speed controller, proximity switch, button switch, and wiring terminal, are all first-class products, ensuring the reliability and long life of the system hardware.

- The perfect safety interlock grating mechanism can protect equipment and operators.

- The graphic display touch screen makes the palletizer simple to operate, easy to diagnose faults, and convenient for overhaul and maintenance at the same time.

What about the de-palletizer?

We can also consider an automatic de-palletizer for water factories with high output and a high degree of automation. De-palletizer, as the name implies, is a machine that automatically unloads empty barrels into the production line. To make the layout reasonable, we can put the de-palletizer and the palletizer in the same area of the workshop. In other words, the de-palletizer unloads the empty barrels for the production line, and the unloaded tray enters the palletizer directly via the tray conveyor for stacking.

The above is an introduction to the 5-gallon barrel palletizer. Welcome to contact us for more details.