It’s hot and a little tired today, and if there’s a bottle of carbonated drink at this time, I think I can bounce back in no time…

When it comes to carbonated drinks, what’s your first thought? Relieve summer heat, quench thirst, cool down…

In the hot summer, drinking a bottle of iced soda can not only relieve the heat and cool down, but also make people feel unspeakably comfortable and meet people’s physiological needs. This function can not be replaced by any other beverage.

What is the carbonated drink?

Carbonated drinks are drinks containing carbon dioxide dissolved in water. The presence of this gas creates bubbles and hissing sounds in the liquid. This hissing sound makes carbonated drinks called “pop” in some places. In addition to pop, in some other places, carbonated drinks are also called soda, sparking water, carbonated water/carbonated drink, gas water/gas drink, aerated water/aerated drinks, fizzy drinks, flavor water/flavor drink, carbonated soft drink(CSD drink, soft drinks are called “soft” in contrast with “hard” alcoholic drinks), energy drink, sports drinks and so on.

The production of carbonated drinks began from the late 18th century to the early 19th century. The initial discovery began with drinking carbonated spring water that naturally gushes out. In other words, the predecessor of carbonated drinks is natural mineral water. Later, it was discovered that the artificial mixing of water and carbon dioxide gas, like natural mineral water containing carbon dioxide gas, has a peculiar flavor, which greatly promoted the manufacturing and research process of carbonated beverages.

Joseph Priestley invented carbonated water, independently and by accident, in 1767 when he discovered a method of infusing water with carbon dioxide after having suspended a bowl of water above a beer vat at a brewery in Leeds, England.

In 1807, the United States introduced juice carbonated water, adding juice to the carbonated water for flavoring. This beverage was popular and began industrial production.

What kinds of carbonated drinks are there?

According to different ingredients, carbonated drinks are divided into cola-type, fruit juice type, fruity type, soda water type, energy type, and so on.

Cola-type carbonated drink

The Cola-type carbonated beverage is a beverage made from kola nut, citric acid, sugar, caramel color, and spices. The most famous brands in the world are Coca Cola and Pepsi Cola.

Fruit-juice type carbonated drink

The fruit juice type carbonated beverage refers to the carbonated beverage containing 2.5% or more natural fruit juice, such as orange soda, pineapple soda, etc.

Fruity-type carbonated drink

The fruity type carbonated beverage refers to the carbonated beverage with food flavor as the main odorant and fruit juice content less than 2.5%, such as lemonade soda, orange soda, and so on.

Soda water type carbonated drink

The soda water type carbonated beverage is a pure carbonated beverage made of soda, which does not contain other fragrances and sugar.

Energy type carbonated drink

The energy type carbonated beverage refers to the carbonated beverage which can replenish the electrolytes and energy lost after human exercises, such as Red Bull, etc.

How to make the carbonated drink?

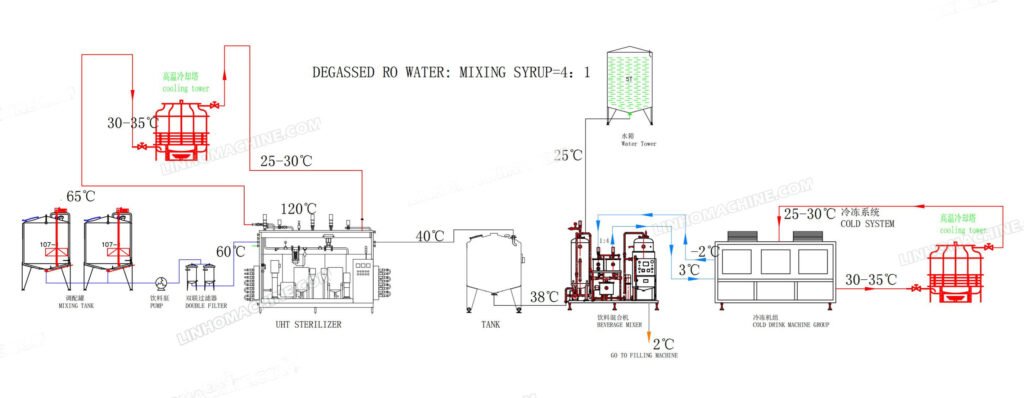

The production process of carbonated beverages varies from different formulas, which can be roughly divided into the following processes.

Water treatment system – Sugar melting – Blending – Carbonation – Cooling- Filling – Labeling – Warming – Packing

If you are making soda or sparkling water(the drink just has water and carbon dioxide), you can skip sugar melting and blending.

Water treatment system

Water is the most predominant ingredient found in the carbonated drink. The quality of water used in carbonated drinks is very important. The inside of water should have no impurities interfering with taste, color, physical appearance, and carbonation.

The selection of water treatment system equipment mainly depends on the quality of raw water. Please refer to the water treatment system article for more details.

Sugar melting

This step is to melt granular sugar into syrup. The tank used for sugar melting is called the sugar melting tank, It is the triple-layer tank, the inner layer is touch materials, the middle layer is heating, and the outer -layer is insulation. It plays some functions as stirring, dissolving, heating(or cooling, use tap-water cooling), filtrating( strainer), and others.

Workers put the granularity sugar into the sugar melting tank, connect the cold water (or hot water) pipe, and heat the inner layer of the tank through steam or electric heating to dissolve the granularity sugar into syrup.

Skip this step if you already have the dissolved syrup in your recipe.

Blending

After the sugar is melted into syrup, we need to fully mix the syrup with other beverage ingredients (such as fruit powder, citric acid, additives, preservatives, etc.). The tank used to dissolve syrups and other ingredients is called the mixing tank(blending tank). We put the required materials into the tank respectively, heat the materials through jacket heating, and then start the stirring system to make all kinds of materials dissolve and mix evenly. The stirring time and temperature in the heating process can be freely set and mastered according to the process requirements to achieve the expected(desired ) concentration and viscosity.

Whether sterilization is required after blending depends on the specific formula.

Carbonation

After blending, we need to carbonate the beverage, that is, injecting carbon dioxide into the beverage. The amount of carbon dioxide injected varies from the different beverages. The carbon dioxide content of fruit-type carbonated beverages is usually lower than that of cola-type carbonated beverages.

The dissolving capacity of carbon dioxide increases with the beverage temperature decreases.

Cooling

Carbon dioxide can only be mixed in the liquid at low temperatures, so we need the chiller to cool the material after mixing. Linho provides air cooling type chiller and water cooling type chiller. Customers can choose freely according to the actual situation.

After blending and cooling the carbonated drink, we usually need CIP cleaning to clean the equipment and pipeline, otherwise the following precipitate will affect the carbonated beverage quality.

CIP cleaning is CLEAN IN PLACE. CIP cleaning is a safe and automatic cleaning system that does not decompose the production equipment and can be easily operated. CIP cleaning can not only clean the machine, but also control microorganisms. Here is the details about CIP cleaning system.

Filling

The selection of the filling machine varies from the material of the bottle. According to the different bottle-material of carbonated drink, the filling machine can be divided into plastic bottle carbonated drink filling machine, glass bottle carbonated drink filling machine(aluminum cap, crown cap, pull ring cap), aluminum bottle carbonated drink filling machine, and can carbonated drink filling machine(metal cans and pet cans), etc. Linho offers a variety of carbonated drink filling machines.

Due to the carbon dioxide, the bottle of carbonated drink is full of bubbles, which affects the filling liquid level. Linho adopts the high-quality filling valve and frequency conversion liquid inlet to ensure the accuracy of filling liquid level.

Labeling

With different bottle materials and different capacity output, the selection of the labeling machine is also different.

Linho can provide you with different labeling machines according to your requirements.

Warming

Because carbonated drinks are generally cooled during the manufacturing process, they must be brought to room temperature before labeling to prevent condensation from ruining the labels. This is usually achieved by spraying the containers with warm water and drying them.

Linho bottle warming tunnel adopts accurate temperature control in different sections to ensure the taste of the carbonated drink.

Packing

Finally, filled carbonated drinks are packed into cartons or trays which are then shipped in larger pallets or crates to distributors, then to your hand.