Water is the source of life and an indispensable natural resource in modern industrial production. In industrial production, our requirements for water are not the same. This requires that we have to use different water treatment to treat water to meet the standards of industrial production.

According to the raw water quality and usage of finished water, we divide water treatment into: sewage treatment, distilled water equipment, softened water treatment, RO water treatment, ultrafiltration water treatment, brackish water treatment, seawater treatment, and deionized water treatment. Linho mainly produces softened water treatment, RO water treatment, ultrafiltration water treatment, brackish water treatment, seawater treatment, and deionized water treatment. Next, we will focus on these water treatments. I believe that after reading this article, you will have a better understanding of what water treatment you need.

Softened Water Treatment

Softened water treatment, as the name suggests, is the machine to soften hard water. This type of raw water contains more Ca, Mg ions. Industrial equipment that uses this type of water for a long time is prone to scale, which seriously affects the use effect and service life of the equipment. The components of scale are mainly calcium carbonate, magnesium carbonate and calcium sulfate. A more common example in life is the kettle we boil water. If you find that there is scale on the inside of your kettle, then you may need a household water softener. In the beverage production industry, soft water is often used in sterilizers, boilers and other equipment that requires hot water.

A complete softened water treatment plant consists of a quartz sand filter, an activated carbon filter, a water softener, and a precision filter. Among them, quartz sand filters and activated carbon filters are collectively referred to as mechanical filters, and their main purpose is to deal with suspended solids, odors and colors in water. In the water treatment article, we have a more detailed introduction to mechanical filters. You can click to view it.

The active ingredient of the water softener is the ion exchange resin. In appearance, ion exchange resins are tiny plastic balls. Each new plastic ball contains cationic sodium. When these plastic balls come into contact with water containing calcium and magnesium ions, the sodium ions in the plastic balls are exchanged with calcium and magnesium ions. After the exchange, calcium and magnesium ions in the water are adsorbed on the resin, and the sodium ions in the original resin enter the water. In this way, the content of calcium and magnesium ions in the water is greatly reduced, and the original hard water becomes soft water.

When all the resins are adsorbed with calcium and magnesium ions, they can no longer work. At this time, the resin needs to be regenerated. Let the saturated resin adequate contact with a large amount of dilute brine (NaCl). A large number of sodium ions in dilute brine displace the calcium and magnesium ions in the resin, and the resin regenerates.

At present, the global famous softening resin brands include Rohm & Haas in the United States, Dow in the United States, LANXESS in Germany, Mitsubishi in Japan, and Purolite in the United Kingdom. Among them American Rohm & Haas, American Dow and British Purolite are brands that uses more. The price is also more expensive. Water treatment producers in China also use Chinese softening resins. Because its effect is good at the same time the price is lower. You can select the right softening resin according to your budget and preference.

RO Water Treatment

RO water treatment full name reverse osmosis water treatment. The osmosis of water is reversed mainly by means of pressurization, and the water is filtered into pure water that hardly contains any dissolved salts through a reverse osmosis membrane. Purified water can be used for the production of various foods and beverages, and can also be directly used to fill pure water into bottles. Raw water used in food and beverage production can be any uncontaminated water source. Such as groundwater, spring water, river water, well water, municipal tap water.

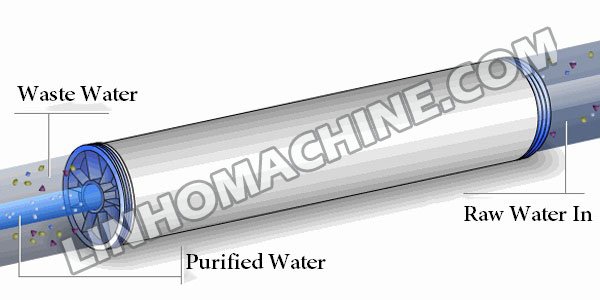

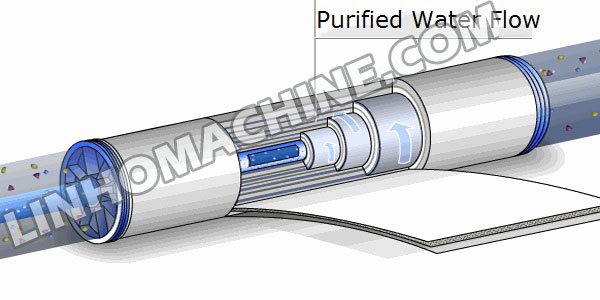

The complete RO water treatment equipment includes a complete set of water soften equipment, plus RO equipment. The core component of the RO device is the RO membrane. You can think of the RO membrane as a filter cloth full of small holes. When water containing dissolved salts, colloids, microorganisms, inorganic substances, bacteria, viruses flows through this filter cloth, we pressurize the water. The water under pressure will quickly pass through the small holes in the cloth to reach the other end of the cloth, while the remaining dissolved salts, colloids and other impurities will continue to stay at this end of the cloth and eventually be discharged with the concentrated water. The water at the other end of the filter cloth is the pure water. The water production rate of RO membrane is 50% to 60%. That is, every 10 tons of raw water entering the RO equipment, 5T ~ 6T of pure water can be obtained.

The filter holes of the RO membrane after prolonged use will be blocked by impurities. At this time, the RO membrane needs to be backwashed to flush away the impurities on the filter hole, and the RO membrane can continue to be used. Depending on the quality of the raw water, the RO membrane needs to be replaced every 2 to 5 years.

The more well-known RO membrane brands in the world are Japan’s Toray, the United States Hydranautics, and the United States DOW. Ro membrane made in China is also very popular in the Chinese market, mainly due to its preferential price and good filtration effect.

Ultrafiltration Water Treatment

Ultrafiltration machine is also known as hollow fiber ultrafiltration machine. It mainly separates harmful substances in water through internal pressure. While purifying raw water, it can also retain minerals in raw water. It is a very good choice for factories with natural and high-quality water sources.

The complete set of ultrafiltration equipment consists of mechanical filters and ultrafiltration units. The ultrafiltration membrane in the ultrafiltration unit is the core of the entire equipment. There are also a large number of filter holes on the ultrafiltration membrane. At atmospheric pressure, substances larger than the pore size, such as sediment, rust, colloids, bacteria, will be retained; while some trace elements will be retained. The yield tax rate of ultrafiltration membranes is close to 100%. That is, for every 10T of raw water, it is possible to obtain nearly 10T of purified water.

Like RO membranes, ultrafiltration membranes require regular flushing. According to the quality of the raw water, the ultrafiltration membrane needs to be replaced every 1-2 years. Common international brands are Japanese Toray, American Hydranautics, American DOW. At present, in China, domestic ultrafiltration membranes are mainly used.

In the past communication with customers, we often encounter such problems. Is ultrafiltration good or RO? In fact, this mainly depends on the quality of the customer’s raw water. Below is a table of ultrafiltration and RO that we have compiled.

| Type | Filtration Accuracy | Heavy Metal Removal Rate | Merit | Shortcoming | Applicable Water Quality | |||||

| RO | 0.0001μm | 98% | Be able to drink directly, Solve the water quality problem completely | There is wastewater High-pressure water pumps are required, which is more expensive There was a little bit of noise | Almost all fresh water | |||||

| UF | 0.01~0.1 μm | 0% | Retain minerals No waste water, no high-pressure water pump, no power consumption, no noise, low price | The filtration is not thorough and is only suitable for high-quality water sources | High quality water |

At the same time, we also list the substances that RO and ultrafiltration can filter separately.

| Filter | RO | UF |

| Large particles of impurities such as sediment and rust | Y | Y |

| Residual chlorine and other odors | Y | Y |

| Volatile organic compounds | Y | Y |

| Macromolecular organics | Y | Y |

| Colloid | Y | Y |

| Bacteria | Y | Y |

| Virus | Y | N |

| Scale | Y | N |

| Heavy metal | Y | N |

From the above analysis, we can see that if the raw water quality is good, there is no heavy metal, virus and other substances smaller than 0.01 microns, ultrafiltration equipment can be used. It not only retains the natural minerals in the water, but also greatly saves the cost.

Deionized Water Treatment

By RO treatment, more than 99% of the ions in the water can be removed. However, there will still be impurities that RO cannot remove. For example, some trace elements, dissolved gases (such as carbon dioxide), some weak electrolytes (such as boron, silicon dioxide). RO is less effective at removing these impurities. However, in some industrial applications, these impurities must be removed. Like what:

- Production of monocrystalline silicon, polycrystalline silicon, solar cells, alumina crucibles, photovoltaic glass

- Production water of electronic semiconductor integrated circuit blocks, the picture tubes, glass shells, liquid crystal displays, etc

- Production water of Non-ferrous metals, precious metals smelting

- Production water of nanoscale new materials, aviation new materials, ITO conductive glass manufacturing, electronic grade dust-free cloth

- Production of batteries, lithium batteries, zinc-manganese batteries

This is where EDI (Electro deionization) is used. EDI is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration technology.

Structure of EDI:

The EDI membrane stack consists of a logarithmic number of units sandwiched between two electrodes. Each unit is divided into a concentrated water chamber and a freshwater chamber by cation/anion exchange membranes. Cation exchange membrane allows only cations to pass through while anion exchange membrane only allows anions. The freshwater chamber is evenly filled with anion and cation exchange resin.

Workflow of EDI:

When impurities such as Na+ and CL- in raw water pass through the freshwater chamber, they are adsorbed on the cation & anion exchange resin. When energized, the water molecules decompose into H+ and OH- under the action of voltage, and the cation & anion exchange resin is continuously regenerated. The cations & anions such as Na+ and CL- in the cation & anion exchange resin are continuously attracted by the corresponding electrodes during the regeneration process. They pass through the cation & anion exchange membrane and get into the concentrated water chamber. H+ and OH- also recombine into water molecules at this time.

EDI devices are often used in conjunction with RO. According to different industrial requirements, some water that requires double stage RO treated water is used as raw water. The ultrapure water yield of EDI is as high as 95%, and the water quality of the water can reach 10 to 15 MΩ. Moreover, EDI does not require acid and alkali regeneration, can be produced continuously, and does not produce sewage. This has led to the development of EDI in industries such as pharmaceuticals, semiconductors, power and surface cleaning, as well as widespread use in wastewater treatment, beverages and microbiology.

Common brands of EDI modules are Siemens, Canpure, Micronix, GE, QUA, Evoqua, SnowPure, New Sky Energy。

Brackish Water And Seawater Treatment Equipment

In areas with insufficient freshwater resources, we need to rely on non-fresh water as raw water for drinking water or domestic water. For example, islands, marine, salt lake areas or sea areas. Brackish water and seawater treatment equipment removes large amounts of salt from water and purifies it into drinking water.

Brackish water and seawater treatment use RO equipment. Due to the complex composition of seawater and the large amount of salt, the RO membrane for seawater must have a high salt removal rate, corrosion resistance, high pressure resistance and pollution resistance. Ordinary RO membranes can only handle water with a TDS up to 2000mg/L. Brackish water RO membrane can treat water up to 8 000mg/L. The seawater RO membrane can treat more than 10,000mg/L of water. TDS 36000mg/L of water can reach 200mg/L after seawater RO treatment. This is better than the quality of tap water.

Brackish water and seawater treatment equipment can also be manufactured modularly. For example, when loaded into a container, it can become a mobile pure water treatment equipment. It can also be mounted directly on a ship for use at sea.

The above is a brief introduction to various common water treatments. If you are considering purchasing water treatment, or have some questions about water treatment, please do not hesitate to contact us. Linho’s professional team will definitely be able to provide you with some ideas.