The epidemic has slowed our pace of life, limited our travel, and altered our purchasing habits. People prefer hoarding daily necessities, large packaging, and online consumption. Large packaging of drinking water has also become popular in the drinking water industry. The large plastic bottles containing water(3-5gallon barrel) come in various expands our options. I’m curious if you pay attention to their materials.

What are the different types of plastic?

If you look closely, you’ll notice that there is a recycling logo with a triangle on the outside and a number inside ranging from 1 to 7 on the bottom of each plastic container.

The symbol is a code for the Society of Plastics Industry’s (SPI) plastic types, with numbers ranging from 1 to 7 representing the type of resin used in plastics. Many countries around the world have now adopted the SPI logo scheme. We’d also like to clarify a common misconception: the triangular logo at the bottom of the bottle denotes recyclable; this “recycling” does not imply that we can reuse the bottle, but can reuse the material. The most common bottle materials in the drinking water industry are PET, PE, and PC; today, we will go over these three types of plastic barrels.

What is the primary material of a 3-5 gallon barrel?

PET

- Digital 1 (PET), the main component of this plastic bucket is polyethylene terephthalate, also known as “PET” for short.

- It is a soft plastic with a high polymer content.

- Its primary application is in the manufacture of mineral water and beverage bottles.

PE

- Polyethylene (PE) is composed of two types of polyethylene: high-density polyethylene HDPE (digital 2) and low-density polyethylene LDPE (digital 4). The density difference causes significant differences in some of their properties.

- The primary application of high-density polyethylene HDPE (digital 2) is milk bottles, juice bottles, household cleaning bottles, bath bottles, and other similar products.

- The primary application of low-density polyethylene LDPE (digital 4) is frozen food preservative film, bread bags, and some food packaging.

- For barrels containing normal temperature water, both high-density polyethylene HDPE (digital 2) and low-density polyethylene LDPE can be used (digital 4).

PC

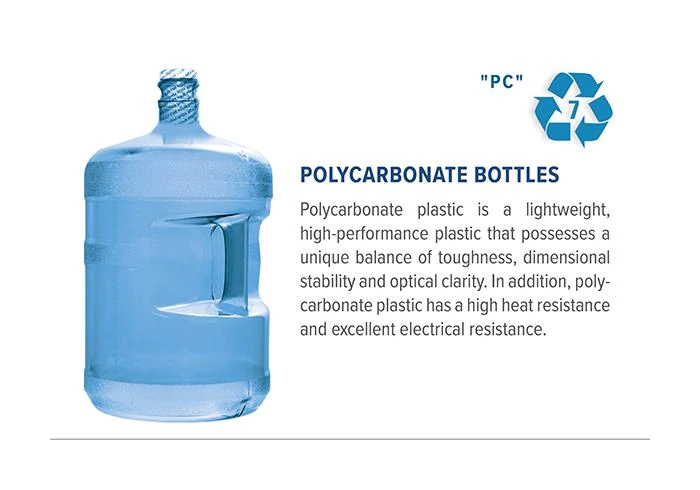

- PC belongs to the digital 7(others) category; the main component of the PC water barrel is polycarbonate, abbreviated PC.

- PC is an engineering plastic, and a PC water barrel is also known as a toughened barrel.

- Typical items include 3-5 gallon water barrels, plastic water cups, sunglasses, mobile phone cases, computer cases, etc.

3-5gallon barrel,PC

The material feature of 3-5 gallon barrel

PET

- PET is a milky white or light yellow, highly-crystalline polymer with a smooth, shiny surface and high transparency.

- PET water barrel’s material is relatively soft and easily deformed after pressurization.

- PET water barrel is not resistant to high temperatures (melting point is around 80 °C), is easily deformed at high temperatures, and decomposes substances harmful to the human body. It is suitable for use in unheated beverage bottles.

- PET plastic has a porous structure, and the pores expand with repeated use. Bacteria can exist in the pores of the plastic, resulting in bacterial accumulation after long-term use.

- The repeated filling of PET water barrels causes some toxic and harmful small molecules to dissolve in the water, it will release carcinogens and endangers human health when exposed to sunlight or heated.

PE

- HDPE has higher melting points, higher hardness, and is more resistant to corrosive liquid corrosion than LDPE.

- Because low-density polyethylene (LDPE) has low heat resistance, avoid using it in high-temperature conditions to avoid hot melting, which can leave some harmful plastic preparations and endanger human health.

PC

- PC is an amorphous thermoplastic resin with exceptional all-around properties.

- The PC water barrel consists of relatively hard material with good mechanical strength, wear resistance, non-deformation, smooth appearance, and uniform texture.

- The PC water barrel is heat resistant (melting point around 280 °C) and can withstand high-temperature disinfection; it can directly contain boiled water.

- The PC water barrel has good electrical insulation, extensibility, dimensional stability, chemical corrosion resistance, and cold resistance. It is also self-extinguishing, flame retardant, non-toxic, and colorable.

What is the price and lifespan of a 3-5 gallon barrel?

PET

- We often use it as a disposable water bucket, and its service life is approximately one year.

- A 5-gallon PET material water bucket costs about $2-5 per unit.

PE

- PE bottle in Middle East is usually use as a disposable water bucket, and its service life is approximately one year.

- A 5-gallon PE water bucket costs approximately $2-4 per unit.

PC

- We often use it as a recycling bucket; the service life of an ordinary PC water bucket is about three years, and a high-quality PC bucket can last for more than ten years.

- A 5-gallon PC material water bucket costs about $3-10 per unit.

What is the barrel-making machine for 3-5 gallon barrel?

The manufacturing of a 3-5 gallon barrel

PET

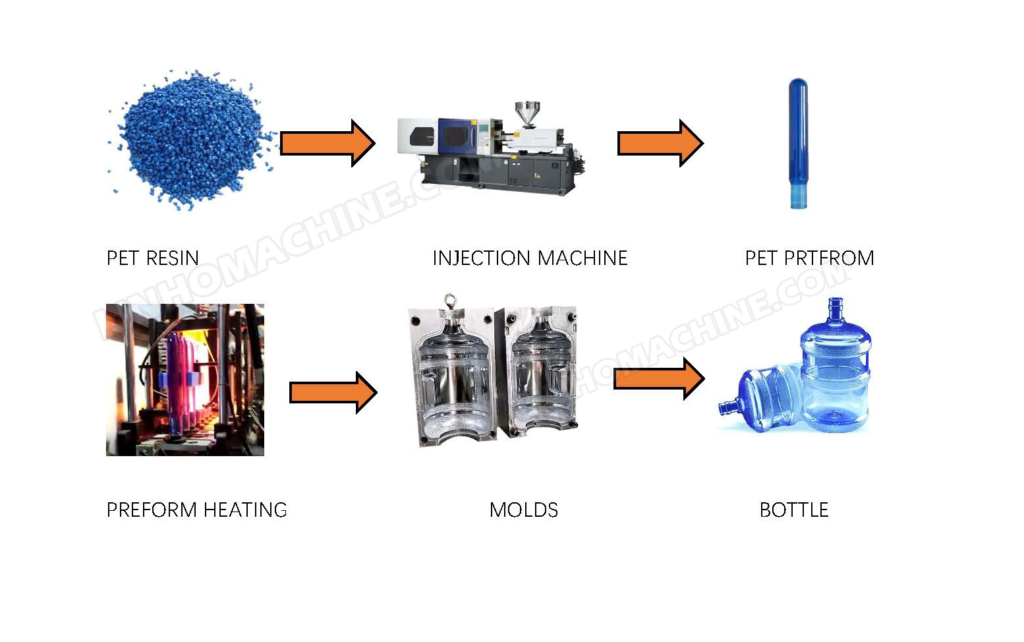

- We use the bottle-blowing machine to make the PET water barrel; the process is to heat the ready-made PET tube preform and then blow it into a barrel shape.

- The PET bottle blowing machine’s entire system consists of the oven, blowing machine, mold, high-pressure air compressor, low-pressure air compressor (optional), cold dryer, air filter, and chiller.

Concerning PET tube preform

We use the injection molding machine to make the PET tube preform. A 5-gallon PET tube preform has an internationally accepted weight range of 650gram-750gram.

A 5-gallon PET tube preform costs around USD 00235/gram in China (equal to USD 1.77 for a 750g PET tube preform), with a lid unit costing around USD 0.044. In recent years, the price of raw materials has been fluctuating, we would pay close attention to the raw material price swings to avoid losses. Preforms and caps for 5-gallon PET tubes are also available from LINHO.

PE

- A PE blow molding machine’s complete system includes a blow molding machine, autoloader, mold, mixer, crusher, air compressor, chiller,and air leak tester.

PC

- We use the blow molding machine to make the PC water bucket; the process is to heat PC particles to form a tube preform and then blow it into bucket shape.

- A PC blow molding machine’s complete system includes a blow molding machine, autoloader, mold, dryer, mold temperature machine, hopper, crush, air compressor, and air leak tester.

The speed and cost of a 3-5gallon barrel making machine

PET

- A semi-automatic PET 5gallon bottle blowing machine produces 90 bottles per hour and costs between $15,000 and $20,000.

- A full-automatic PET 5gallon bottle blowing machine produces 1000-2000 bottles per hour and costs between $100,000 and $150,000.

- The cylinder and servo types of full-automatic bottle blowing machines are available.

- Servo-type machines are more energy-efficient, efficient, and pricey than cylinder-type machines.

- There are two types of mold materials: iron mold and aluminum mold.

- The iron mold has high mechanical strength, whereas the aluminum mold is lighter and easier to replace.

PE

- The PE 5gallon blow molding machine has a speed of fewer than 100 barrels per hour and costs between $100,000 and $200,000.

PC

- The PC 5gallon blow molding machine has a speed of fewer than 100 barrels per hour and costs between $100,000 and $200,000.

When we choose 3-5gallon barrel, we need consider material, barrel lifespan, and barrel making machine. Linho will recommend the right 3-5gallon barrel machine according to the customer’s budget, product details, and production line size. Contact us for your exclusive solution!