Carbonated beverage refers to the carbonated, non-alcoholic beverage. Whether you call it soda, pop, sparkling water, coke, or fizzy drinks, carbonated beverages are very popular across the world, especially for those people who don’t drink alcohol, carbonated beverages are undoubtedly one of their favorite drinks.

How to open a carbonated beverages factory? In previous articles, we have discussed how to make carbonated beverages and the formula of carbonated beverages. Now let’s discuss the packaging of carbonated beverages. We know that in the market, the containers for filling carbonated beverages include plastic bottles, glass bottles, aluminum bottles, and cans. In today’s article, let’s talk about the production line of plastic bottled carbonated beverages in detail.

Containers for carbonated beverage

How is the plastic bottle made?

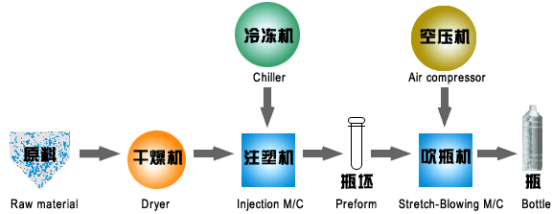

Plastic particle-injection molding machine-bottle blowing machine

Carbonated beverage bottle

You may have noticed that the bottle body of carbonated beverages is usually smooth without lines. The lines on the plastic bottle, we also call stiffener, the main function is to strengthen the bottle hardness. A bottle with lines is usually stronger than a bottle without lines. So why don’t carbonated beverage bottles use lines? That is because carbonated beverages contain carbon dioxide. When the liquid containing carbon dioxide is filled into the plastic bottle, the bottle becomes very strong due to the pressure in the bottle, and no need for the lines to make the bottle strong. If we use a bottle with lines to fill carbonated beverages, the lines of the bottle body will become concave due to the pressure in the bottle, which will affect the filling liquid level of the carbonated beverages in the bottle.

Similarly, we can explain why the bottle bottom of carbonated beverages has five points. If the bottle bottom of carbonated beverages is as flat as a water bottle, the bottle bottom will bulge out due to pressure when we fill carbonated beverages into the bottle.

Carbonated beverage bottle neck

We know that the bottle mouth of carbonated beverages is usually smaller than the bottle mouth of water bottles, that is because the smaller bottle mouth is better for keeping carbonated beverages fresh. There’s another detail you may not have noticed. That’s the bottle mouth of the carbonated beverages, usually with a gap. The main function of this gap is to relieve pressure. When we open a bottle of carbonated beverage, the gap at the bottle mouth can relieve the pressure, so that the carbonated beverages will not suddenly gush out and splash everywhere. The caps of carbonated beverages usually have a sealing gasket inside, which is also used to keep them fresh.

How much the price of the carbonated beverage bottle preform and cap?

Generally speaking, beverage manufacturers buy ready-made bottle preform from bottle preform manufacturers to blow bottles. Mainly because the bottle preform is the standard part, and the injection molding machine for making bottle preform and bottle cap also needs professional technicians to operate and maintain. Under the influence of petroleum, the price of bottle preform and bottle caps varies from country to country. When we find cheap bottle preform manufacturers, besides checking its quality, transparency, and accuracy, don’t forget to add the shipping fee. This year, due to the rising price of raw materials, the price of bottle preform is also rising. At present, the price of bottle preform in China is $0.0019 per gram, with the caps about $0.0118 per piece(500ml carbonated beverage bottle is usually 22g, which means that the price of each bottle preform is $0.0418).

Besides the bottle-making system, what machines are there in the plastic bottled carbonated beverage production line?

1.Washing Filling Capping 3 in 1 Machine-2. Bottle Warmer Tunnel-3.BlowDrying Machine-4.Labeling Machine-5.Date Printer-6.Inspection Machine-7.Packing Machine

1. Washing Filling Capping 3 in 1 Machine

Washing part

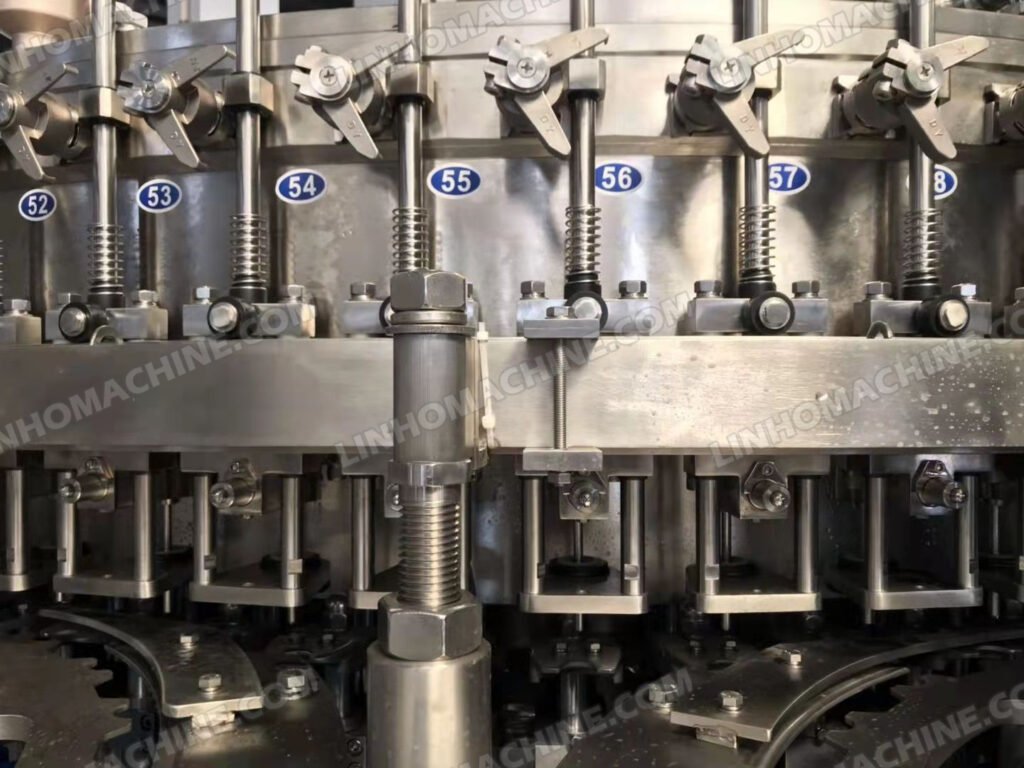

The working process of bottle washing machine: the bottle clamp of the bottle washing machine clamps the bottle mouth and turns it 180 ° along a guide rail to make the bottle mouth downward, in the specific area of the bottle washing machine, the special nozzle sprays bottle washing water to wash the inner wall of the bottle. After the bottle is washed and drained, it is clamped by the bottle clamp and turned 180 ° along the guide rail, so that the bottle mouth is upward and then transmitted to the filling machine.

Linho bottle washing machine adopts the unique turnover bottle clamp to avoid bottle mouth pollution caused by traditional rubber clamp. The high-efficiency atomizing nozzle on the bottle clamp can clean any part of the bottle inner wall and save washing water. The sink assembly is used to collect the bottle washing water, which can avoid the waste of the bottle washing water as far as possible, and achieve centralized discharge or centralized recovery.

Filling part

The filling of carbonated beverages is divided into the primary filling and the secondary filling.

The premix filling

The one-time filling is also called premix filling. The syrup and water enter into the carbonated beverages mixer through the pump in a certain ratio, mixed quantitatively and then cooled, and then the mixture is carbonated and filled.

- The disadvantage of the premix filling: it is not suitable for filling the carbonated beverages with fruit pulp, and the mixing equipment is complex which washing is inconvenient.

- The advantage of the premix filling: the proportion of syrup and water is accurate, and the filling amount is easy to control, if changing the filling bottle volume, the proportion does not need to be changed. During filling, the temperature of syrup and water is the same, less foaming, and the content of CO2 gas is easy to control and stabilize.

Product quality is stable, CO2 gas content is sufficient, production speed is fast, has become the development direction of carbonated beverages production.

The postmix filling

The secondary filling is also called postmix filling. The secondary filling system is divided into two steps, syrup filling machine(also known as grouting machine or quantitative machine) and carbonated water filling machine.

- The advantage of the postmix filling: syrup and carbonated water are independent systems, the equipment is simple and the pipeline is easy to clean, especially suitable for filling carbonated beverages with fruit pulp.

- The disadvantage of the postmix filling: when we fill carbonated water into syrup, it is easy to produce a lot of foam, resulting in the loss of carbon dioxide. In the postmix filling, when changing the bottle volume, the amount of syrup and carbonated water needs to be adjusted, otherwise, it is easy to cause the difference in product quality.

How to reduce the foam and reduce the contact chance between air and carbonated beverage?

The filling principle of carbonated beverages adopts isobaric filling, that is, when the pressure in the bottle is equal to the pressure of the filling tank, the filling valve is opened under the action of spring, and the filling liquid is filled into the bottle by gravity. When filling carbonated beverages, the most important thing is to reduce the contact between the beverages with the air (to ensure the taste of the beverages) and remove the foam (otherwise affect the filling level).

Before filling, Linho adopts the diaphragm device to achieve the effect of variable frequency liquid intake, reducing a lot of foam into the filling tank.

When filling, use a shunt umbrella to fill carbonated beverages along the bottle wall to reduce the generation of foam.

After filling, close the filling valve, open the exhaust rod to relieve pressure in the bottle, prevent foam from eversion.

Linho adopts the filling valve of German high-quality technology to fill carbonated beverages to control the sealing of filling and the accuracy of filling level. We use washing filling and capping 3 in 1 structure, compact structure reduces the contact time between beverages and air after filling.

Capping part

After filling, the bottle filled with beverage goes into the capping machine for capping. Under the action of the cam, the capping head realizes the actions of caps grasping, caps sleeving, caps screwing, and caps dropping, and completes the whole capping process. To prevent accidents, Linho put an anti-reverse cap dial wheel on the caps falling guide rail to ensure the direction of the caps is correct.

2. Bottle Warmer Tunnel

Due to carbon dioxide, the filling of the carbonated beverages is usually cold-filled (0-5 degrees). After filling and capping, it must be brought to room temperature before labeling to prevent condensation from ruining the labels. That is usually achieved by spraying the bottled carbonated beverages with warm water and drying them.

Linho bottle warming tunnel adopts accurate temperature control in different sections to ensure the taste of the carbonated beverages.

3. Blow Drying Machine

After the carbonated beverages come out of the tunnel, the bottle body is full of water droplets. We need a blow dryer to dry the bottle, otherwise, it will affect the following labeling and packaging production. Linho blow-drying machine adopts spider hand nozzles, all nozzles can adjust the direction and height arbitrarily to achieve all-round drying of bottles.

4. Labeling Machine

The labeling methods of plastic bottle carbonated beverages are mainly sleeve&shrink label machine and OPP hot melt label stick machine.

The sleeve&shrink label machine

The sleeve&shrink label machine includes two parts: label sleeving machine and label shrinking machine. The label sleeving machine sleeves the circular label onto the bottle, cuts off the label, enters the shrinking machine, and perfectly shrinks the label onto the bottle through steam shrinkage. The accuracy of the labeling is high, and bottle shape can be improved after shrinkage.

The maximum output of the low-speed sleeve&shrink label machine is 9000 bottles per hour (the specific output depends on the label size), and the output of medium and high-speeds is about 12000 to 20000 bottles per hour.

OPP hot melt label stick machine

OPP hot melt label stick machine sticks the label head part and the end part together by glue. Heating the glue in solid state at room temperature melted into liquid, coated the glue onto the head part and the end part of the label, then stick them together, pressed and cooled, which is a whole process of labeling.

According to the machine type, it can be divided into linear type label machine(8000-12000BPH) and rotary type label machine (12000-36000BPH). The linear type is mainly used for low-speed production lines, while the rotary type is used for high-speed production lines.

Choose the sleeve&shrink label machine or the OPP hot melt label stick machine?

In addition to considering the machine cost, we also need to consider the label cost.When the output is less than 9000bottles per hour, the cost of the OPP hot melt label stick machine is about double that of the sleeve&shrink label machine, but the label used in the hot melt label machine is about 30-40% cheaper than the label used in the sleeve&shrink label machine.

Therefore, the hot melt label stick machine is more suitable for production lines with high output. After all, for large production lines, long time running, the label cost is also very high.

5. Date Printer

For the date printer, it has ink type and laser type. The same efficiency of the date printer, ink is cheaper than laser. The difference can be as high as $10,000. The ink type date printer needs to buy ink consumables and needs to clean to prevent ink blockage after a long time of use. Relatively speaking, the laser type date printer is much more convenient. The laser-type date printer requires almost no consumption parts and has few problems.

The most popular printer brands on the market today are Linxin from the UK, Imajet from France, Videojet from the US. You also can check the local date printer price.

6. Inspection machine

The inspection equipment includes manual visual inspection and machine inspection.

The machine inspection, also known as X-ray detection, is mainly to inspect and separate the products with insufficient liquid levels and unqualified caps in the finished products. Some inspection machines also can separate the bottle with unclear production dates or wrong label position.

The lamp inspection device with ultraviolet lamp tube is mainly to inspect whether there are abnormal particles in the filled carbonated beverage bottle.

7. Packing Machine

We usually use PE film to pack the plastic bottled carbonated beverage. The PE film packing/wrapping machine has the single roll film packing machine and the double roll film packing machine. Single roll film means that the PE film used on the packing machine is a single roll, while the PE film of double roll film machine needs a double roll.

The minimum speed of the single roll film machine is 20packages per minute, which is mainly suitable for the high-speed line. The minimum speed of the double roll film machine is 6-10packages per minute, which is for the medium and low-speed production line. For the same efficiency, the price of the single roll film machine is usually twice that of the double roll film machine.

In addition to the high speed, the single roll film machine can also wrap color printed film( need positioning). If you are a small investor, you can choose the cheap double roll film machine. If the output of your line is high, and you want to use color-printed film then the single roll film machine is a good choice.

Besides the PE film, we also can use cartons to pack the plastic bottled carbonated beverage. If the output of your production line is high and local labor is expensive, you can also choose the palletizer for automatic palletizing and storage.

This is the whole production line of the plastic bottle carbonated beverages, from plastic bottle blowing machine to final packaging. I believe that through this article, you already have a general understanding of this production line, if you have any questions, please feel free to contact us. We look forward to talking with you!