Continue with the previous article: part 1 of Industrial Water Treatment Flow Chat, Here we will talk about where they are applicable:

Ultrafiltration is a suitable technology for treating water sources that contain high concentrations of suspended solids and colloidal substances, such as lakes, rivers, and some groundwater sources. The ultrafiltration process effectively removes these contaminants, producing product water that is suitable for various applications, including drinking water, industrial water, and electronic industry water.

Nanofiltration is suitable for removing dissolved salts and organic substances from water sources, such as seawater desalination, demineralized water treatment, drinking water treatment, and pure water production. The water treated with nanofiltration can be used as a pre-treatment for reverse osmosis.

Reverse osmosis is a suitable technology for treating water sources with high salinity, such as seawater, saltwater, and deep groundwater. The product water from reverse osmosis treatment is suitable for various applications, including electronic industry water, drinking water, and industrial water. However, it is important to note that the reverse osmosis process also removes trace elements from the water, which may require the addition of mineral supplements in some special cases to restore essential nutrients in the water.

Ozone generators and UV sterilizers are effective tools for disinfecting and sterilizing water to meet health and safety standards. The ozone generator oxidizes organic matter and odors in the water quickly and effectively, while the ultraviolet sterilizer uses ultraviolet light to kill bacteria and viruses in the water.

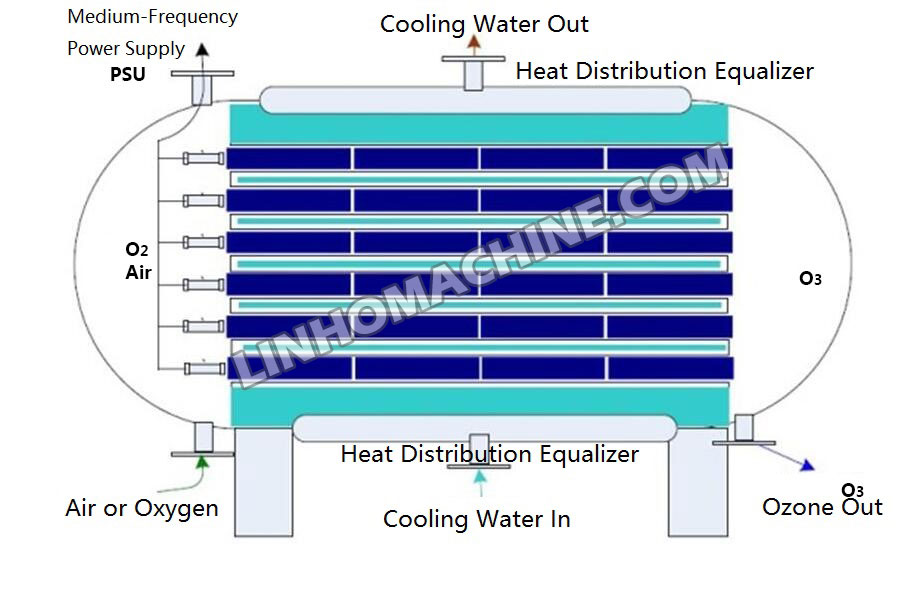

Water Treatment Ozone

Ozone treatment is effective in eliminating odors, colors, and harmful microorganisms in water. It can also decompose organic pollutants in water and kill bacteria and viruses. This treatment is commonly used for water disinfection and odor/color removal, and requires a dedicated ozone generator.

Ozone oxygenation is effective in decomposing both organic and inorganic substances in water, but the presence of certain substances can affect its efficacy.

- Iron-manganese ions: Ozone can oxidize iron-manganese ions into precipitates, but high concentrations of these ions can hinder the efficiency of ozone oxidation and lead to the production of a significant number of precipitated substances, which can negatively impact the normal operation of the equipment.

- Ammonia nitrogen: Ozone can oxidize ammonia nitrogen to nitrate. However, when dealing with water that contains high concentrations of ammonia nitrogen, ozone can produce a significant amount of nitrogen oxide substances that can lead to environmental pollution. Therefore, the use of ozone should be implemented under suitable conditions.

- Organic matter: When water has a high organic content, ozone treatment can lead to the formation of many ozone compounds, which can cause environmental pollution. Therefore, it is important to use ozone treatment with caution when dealing with water bodies that have high organic content. During ozone oxygenation, some refractory substances such as sulfide and cyanide can decompose into toxic by-products, potentially leading to pollution of the environment.

- Bromide: During the process of ozone treatment, if the water contains bromide, it can result in the production of the ozone compound ozonated bromide (OBO), which may produce harmful substances such as bromate. Bromate is known to be carcinogenic and teratogenic, thus it is important to control the content of bromide during ozone treatment. To avoid excessive production of bromate, parameters such as ozone treatment time, ozone concentration, and pH can be adjusted to regulate the formation of ozone compounds.

Before using ozone to treat water, it’s essential to analyze the water quality to determine its chemical composition and concentration. This information will help in selecting the appropriate treatment scheme to ensure effective ozone treatment.

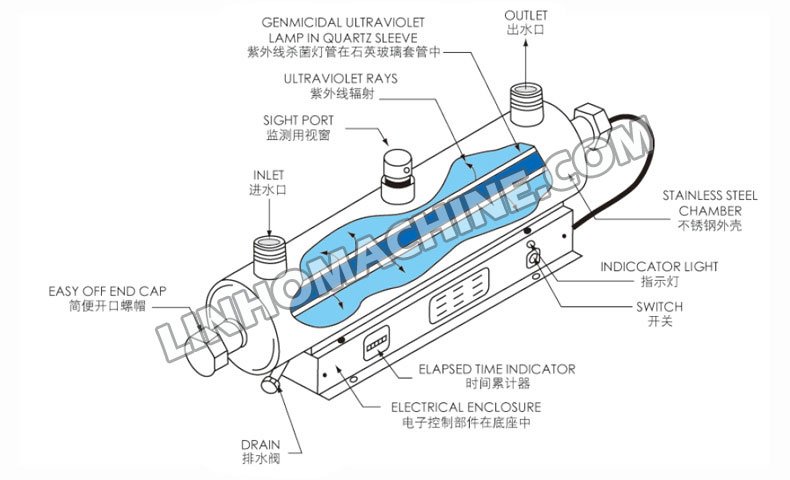

Water Treatment UV

UV sterilization is a chemical-free method that effectively kills viruses, bacteria, and other microorganisms in water without causing any side effects. It utilizes ultraviolet light to destroy the DNA of the microorganisms, rendering them harmless. A specialized UV sterilizer equipped with germicidal lamps is required for this process.

UV lamps are commonly used in water treatment to kill microorganisms without the need for chemicals or other additives, and without any negative impact on the water. The two most common types of UV lamps used in water treatment are low-pressure mercury lamps and medium-pressure mercury lamps. Low-pressure mercury lamps are typically used for disinfection and oxidation, while medium-pressure mercury lamps are primarily used for photocatalytic oxidation.

- A low-pressure mercury lamp emits ultraviolet light primarily at a wavelength of approximately 254 nanometers. It operates at lower voltages and currents compared to other types of lamps. These lamps are commonly used for various applications, including water treatment, air purification, and surface disinfection, for both domestic and light commercial purposes.

- A medium-pressure mercury lamp is a high-power ultraviolet lamp that operates in the wavelength range of 200-400 nanometers. It uses a high-power mercury lamp that provides higher radiation capacity in a shorter period. These lamps are typically used for industrial and commercial applications, such as drinking water disinfection, medical equipment disinfection, and sewage treatment.

Here are some common wavelengths of UV light that affect different microorganisms and contaminants:

- 254 nanometers: it is the most commonly used wavelength in water treatment. It can effectively destroy the DNA molecules of bacteria, viruses, fungi, and other microorganisms, preventing them from replicating and growing. Additionally, this wavelength is effective in removing volatile organic compounds, odors, and colors from the water185 nm: This is the wavelength produced by the ozone generator to produce ozone gas to oxidize organic pollutants in water, such as formaldehyde and benzene.

- 222 nanometers: it is a relatively new wavelength that can effectively kill viruses and bacteria in the air without causing harm to humans. It is important to note that the sensitivity of different types of microorganisms and pollutants to ultraviolet rays varies, and therefore different water treatment systems need to select the appropriate ultraviolet wavelength to achieve optimal disinfection efficacy.

Depending on water quality, treatment requirements, and equipment characteristics, ozone and UV light may be chosen for water treatment. Sometimes, both methods may be used together to achieve a more comprehensive disinfection and purification of the water.