With the improvement of people’s living standards, people pay more and more attention to the quality and safety of food, requiring nutrition, original flavor, longer shelf life, and fresh taste, food sterilization machine has also become more and more important.

What is sterilization machine?

Sterilization machinery generally refers to a machine that kills microorganisms on products, packaging containers, packaging materials, etc., and reduces the number of microorganisms to the allowable range.

In the beverage industry, sterilization usually has two requirements, kill the pathogenic bacteria in the beverage, destroy the enzymes in the food, make the drink in packaging containers have a certain shelf life, the other is to protect the nutritional components and flavor in the beverage as much as possible.

Sterilization machine types

The development of sterilization machinery is developing with food packaging materials and food processing technology. With the progress of technology and the improvement of people’s living standards, a lot of new packaging materials, new food processing technology emerged, different food sterilization equipment also come into being.

Food sterilization methods include physical sterilization and chemical sterilization. Chemical sterilization mainly uses hydrogen peroxide, hypochlorous acid, and other fungicides to kill microorganisms, easy operation, but chemical residues affect food safety. Modern food sterilization usually adopts physical sterilization.

According to the sterilization energy, it has hot sterilization and cold sterilization.

- Hot sterilization has pasteurization, high-temperature short-time sterilization, and ultra-high temperature instantaneous sterilization.

- Cold sterilization includes ozone sterilization, ultraviolet sterilization, radiation sterilization, etc.

According to the inlet and outlet form of the container, it has intermittent sterilization and continuous sterilization.

According to the sterilization temperature, it has atmospheric sterilization and high-pressure sterilization.

According to the structure of sterilization equipment, it has plate sterilization, tube sterilization, and autoclave.

According to the sterilization procedure, it has front sterilization (sterilization during processing) and secondary sterilization (sterilization after packaging).

Today, we talk about three kinds of secondary sterilization equipment commonly used in the beverage machinery industry.

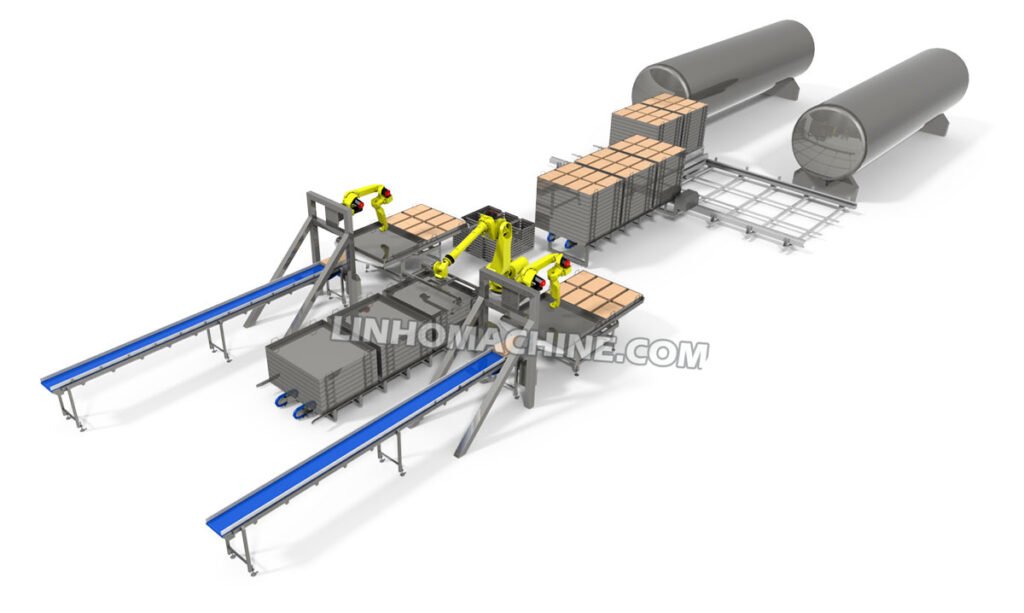

The autoclave/retort

Sterilization kettle is also called sterilization pot or autoclave. The autoclave is closed and pressurized, used for sterilizing sealed food in the container. The autoclave has the advantages of fast heating speed, short heat treatment time, less loss of food color, flavor and nutrients, etc. The autoclave consists of a pot body, pot cover, track, sterilization basket, steam nozzle, etc.

Applicable sterilizing drinks

It applies nonacidic drinks (protein drinks) with a pH greater than 4.5, not suitable for fruit juice.

Autoclave types

According to the external structure, it has the vertical autoclave and the horizontal autoclave.

According to the sterilization methods, it has steam sterilization type, water bath sterilization type, upper spray sterilization type, and side spray sterilization type.

According to the type of sterilization machinery, it has static type autoclave and rotary type autoclave.

Linho autoclave advantages

- Temperature rise is fast, no secondary pollution. Using the high-efficiency heat exchanger, the circulating water in the pot can quickly raise the tem[erature from 20℃ to 121℃ within 10~15min. The circulating water in the tank is heated or cooled indirectly through the plate heat exchanger and remains aseptic all the time. After sterilization, the water droplets on the surface of the package will not leave small-scale spots after drying, and the container is clean without secondary pollution.

- Stable temperature, uniform heat distribution, suitable for fragile bottle sterilization. Linho hot water spray system, on the four corners of each tray in the treatment tank, is equipped with nozzles to make the atomized hot water in contact with the product, to ensure the consistent temperature in all parts of the equipment and avoid breakage of glass bottles due to excessive temperature difference.

- The stable pressure control for gas-containing drinks. The pressure balance system is vital for the sterilization of gas-containing beverages. Linho control system can continuously monitor the temperature and pressure in the treatment tank. We also can adjust the pressure to make it equal to the pressure in the container, and the container and drinks will not be damaged or deformed.

- Fully automatic control system. PLC controls the whole sterilization process. According to the requirements of different drinks for sterilization conditions, can set heating and cooling procedures at any time. We can use multi-stage heating sterilization to preserve drink color, aroma, and taste as perfectly as possible so that each drink can be in the best state of sterilization.

- Save energy. The steam condensed water recovery system can directly recover the condensed water during the heating process, used for sterilization, to reduce energy consumption.

Spray/pasteurization sterilization tunnel

Spray sterilization cooling tunnel, also known as pasteurization tunnel. The tunnel consists of preheating areas, sterilization areas, and cooling areas. We can make the different process design according to the requirements products. Spray sterilization has the advantages of automatic program control, convenient operation, stable and reliable operation, beautiful appearance, and so on. It is ideal sterilization equipment for a modern beverage factory.

Applicable sterilizing drinks

It applies to the secondary sterilization of fruit juice drinks, tea drinks, beer, etc. pack in various plastic bottles, glass bottles, cans, and other packaging forms.

With slight improvement, we also can use it for the warming of gas-containing drinks, the heat preservation, and cooling of hot filling drinks.

Linho spray sterilization advantages

- Fast temperature rise, save energy. Using the high-efficiency heat exchanger to increase the heat exchange area, shorten the heating time and save energy consumption.

- Accurate temperature control. Adopt the imported temperature sensing device, high precision, effective sterilization, and energy-saving at the same time.

- Each section’s temperature is stable, uniform heat distribution (preheating, high-temperature sterilization, precooling, cooling area), efficient sterilization while preventing the breakage of fragile bottles such as glass caused by unstable and uneven temperature.

- High-quality mesh belt chain plate, which can work under high temperature for a long time;

- Wide-angle nozzle, no blockage, large and uniform flow.

- Adopt insulation technology to reduce energy consumption;

- Comprehensive utilization of various energy and heat recovery technologies, energy-saving, and environmental protection.

- The automatic system can monitor and record the temperature changes in the production process.

Bottle inverse sterilization

The bottle inverse sterilizer is special supporting equipment developed according to the process characteristics of the high-temperature filling production line. It tilts the products after filling and capping and uses the high temperature of the products to sterilize the bottle mouth and the inner wall of the bottle cap within a certain time to ensure the quality of the products.

The product in the conveying process can do implement automatic bottle inverse, delayed sterilization, and automatic standing. The process is stable and reliable, and the sterilization time is also adjustable according to needs. In the sterilization process, only the high temperature of the beverage in the bottle sterilize the bottle mouth and the inner wall of the bottle cap, without increasing any heat source to achieve the purpose of energy-saving.

Applicable sterilizing drinks

It is suitable for sterilizing the parts of the bottle mouth and the inner wall of the bottle cap after hot filling of fruit juice, tea, and other beverages packaged in PET polyester bottles.

Linho bottle inverse sterilization advantages

- Adopt imported chain accessories, stainless steel frames to prolong the service life of the equipment.

- Adopt imported heat-resistant anti-skid chain plate to realize automatic turnover, sterilization, and self-reset, high reliability of operation.

When we choose sterilization machine, we need consider beverage types, bottle material, and energy consumption. Linho will recommend the right sterilization machine according to the customer’s budget, product details, and energy consumption. Contact us for your exclusive solution!